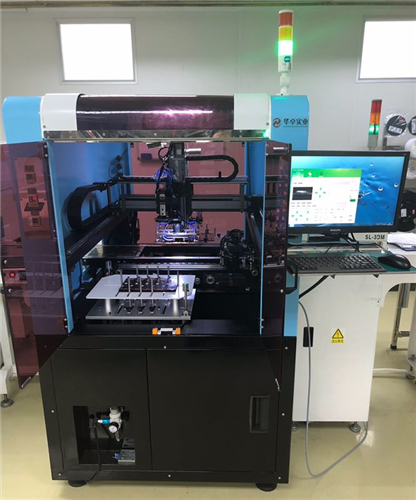

SMT upper and lower board machine

Product classification:Dispensing

Function Overview:

1. Binding range: 70 * 70-L360 * W250 (unit: mm)

2. Fitting accuracy: ± 0.05mm

3. Capacity:< 12S\/PCS (approximately 300PCS\/H)

4. Positioning method: FPC soft board CCD photography positioning, steel plate mechanical positioning, both can be compensated

5. CCD judgment accuracy: ± 0.03mm

6. Compensation range: X-axis, Y-axis: ± 3mm, rotation angle: ± 3 °

7. Fixture: Magnetic fixture+steel sheet

8. Steel sheet: Place one piece on each fixture of the steel sheet; The maximum size of the steel sheet is 380mm * 260mm; Thickness< 0.5mm

9. Stacking thickness of feeding tray: FPC loading height< 100mm; Steel sheet loading height< 100mm

10. Product incoming materials: Single sided and double-sided board sheet size 360mm * 250mm; The deviation of the external dimensions of the incoming materials is ± 2mm; Incoming materials can be stacked into a stack; Stacking can be carried with partition paper

11. Control system: industrial computer+CCD positioning+servo stepper drive, material cut-off alarm, safety access control, suction vacuum monitoring alarm.

12. Installation environment: Boundary dimensions: L1500 * W1000 * H1600; Power: 220V 50Hz Air pressure: 5-7 kgf\/cm2 Environmental humidity: below 80RH

13. Equipment features:

1. Three axis arm: The robotic arm is responsible for assembling FPC soft and hard boards and vehicle steel sheets, achieving high efficiency;

2. Labor saving: One person is responsible for managing 4 or more machines, and the personnel only need to be responsible for changing the loading tray;

3. Avoiding work-related injuries: Human hands do not need to reach inside the docking station to prevent work-related injuries;

4. Stable production capacity: high degree of automation, stable and reliable; Reduce the impact of labor fatigue, inexperience of beginners, and other factors on production capacity;

5. Ready to use: Install before the original SMT reflow soldering or wave soldering, without changing the carrier, product layout, or modifying the SMT reflow soldering or wave soldering;

6. Small footprint: The equipment is installed in front of SMT reflow soldering or wave soldering, with a small footprint;

7. Beautiful and atmospheric appearance: closely following fashionable and popular elements, beautiful and generous;

8. Enhance factory image: Leading the trend of Industry 4.0 automation and enhancing customer competitive advantage;